Description

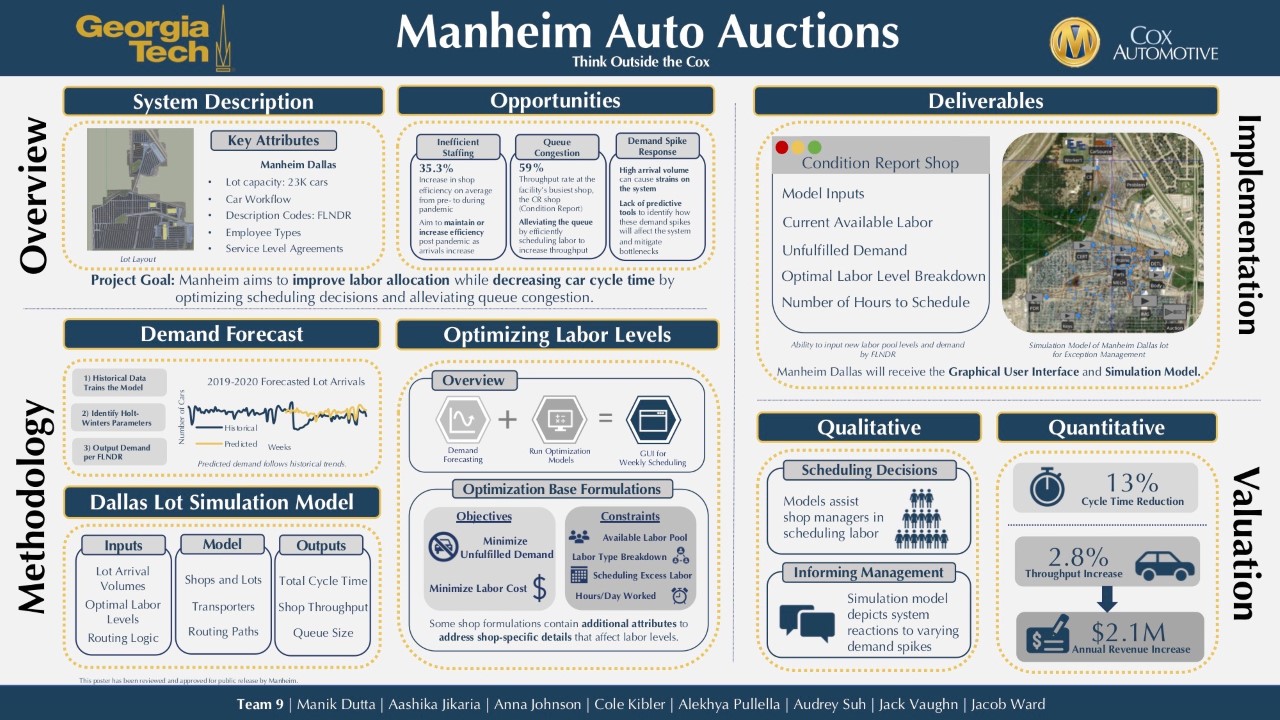

Our client, Manheim, Inc., is a wholesale auto auction industry leader in buying and selling used vehicles through auto-auctions. Specifically, the Manheim Dallas facility has seen an increase in labor efficiency since COVID-19. The team at Dallas would like to maintain these efficiency levels once COVID’s impact lessens and lower vehicle cycle time. We have identified two areas of improvement: Vehicle Throughput and Optimal Staffing. In order to increase efficiency at the lot, Manheim hopes to lower vehicle cycle times as arrival volumes vary. Maintaining efficient staffing based on dynamic arrivals is vital when optimizing labor costs and backlog hours. Adjusting Manheim’s labor levels based on the needs of sub-shops can increase shop throughput resulting in a decreased cycle time. We plan to create a Staff Scheduling Optimization Tool and a Dynamic System Simulation Model. The optimization tool will minimize cycle time and labor cost, providing Manheim Dallas with the optimal labor levels per station, which will depend on forecasted arrival data. The simulation model will reflect the current system, quantify the effects of changes to the system based on the results from the optimization tool, and model the changes on the system when subject to exceptional demand volumes. Through these deliverables, Manheim Dallas will be able to decrease overall vehicle cycle times, increasing their lot efficiency as volume arrivals increase after the COVID-19 pandemic. These benefits will significantly improve Manheim’s ability to take on more volume and therefore increase revenue.

| Department |

Industrial & Systems Engineering |

| Sponsor |

Manheim |

| Advisor |

Dr. Ben Wang |

| Primary Email Contact |

ajohnson434@gatech.edu |

| Table # |

06-K |

Members

| Name |

Major |

Hometown |

| Aashika Jikaria |

IE |

Brooklyn, NY |

| Alekhya Pullella |

IE |

Marietta, GA |

| Anna Johnson |

IE |

Alpharetta, Georgia |

| Audrey Suh |

IE |

Scarsdale, NY |

| Cole Kibler |

IE |

Johns Creek, GA |

| Jack Vaughn |

IE |

Peachtree City, GA |

| Jacob Ward |

IE |

Suwanee, GA |

| Manik Dutta |

IE |

Cumming, GA |

|

|